Category: Suspension

Tuesday, 6 May 2008 | | Categories: Brakes, Engine, Exterior, Driveline, Suspension

A number of weeks ago now, I did a photoshoot with Rick McDowell, a well known WA based photo journalist. The results of which were brilliant, but with a fair amount of work gone into the undercarriage, and an award to prove it, we needed to get some photos done of the underbelly along with additional engine and interior shots. This being something best done on a hoist of course, so last Saturday we were lucky enough to get some time on the hoist in the C-Red workshop (thanks to Marc, C-Red's Workshop Manager). I went in and first detailed the engine bay, which wasn't too bad really. But as I drive this on a daily basis, and that the road near work as had some work done on it recently (plus rain), I had quite a lot of dirt and mud built up under the guards. With the help of the trusty truck wash and a bit of elbow grease (and mess on the floor) the front and rear suspension on the passenger side came up a treat.

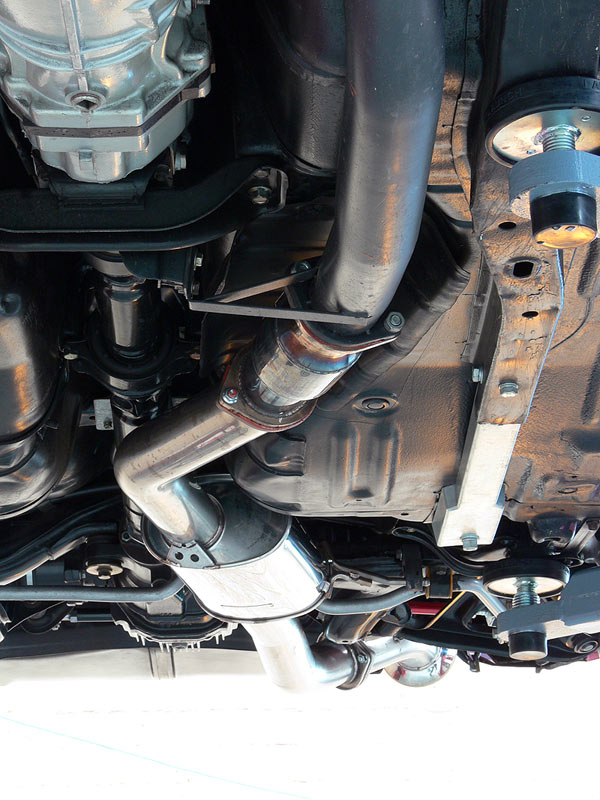

While Rick was snapping away, I thought I'd take the chance to update the undercarriage shots...being there's no longer the Ikeya Formula lower control arms in place, and the exhaust has been completed and changed since the last set I did 6mths ago or so. A couple of things to note though, first being the URAS Floor Reinforcement Kit which extends the chassis rail on the passenger side from the usual S13 cutoff point to the rear. Also, if you look on the drivers side, there's dirt there just to prove that it does indeed get driven. On a whole, I was surprised at how clean the undercarriage is considering the rain we've had lately. Having the fresh'ish paint surfaces certainly helped in cleaning it all up easily though.

Anyway, photos for all to enjoy:

- Rick taking his photos

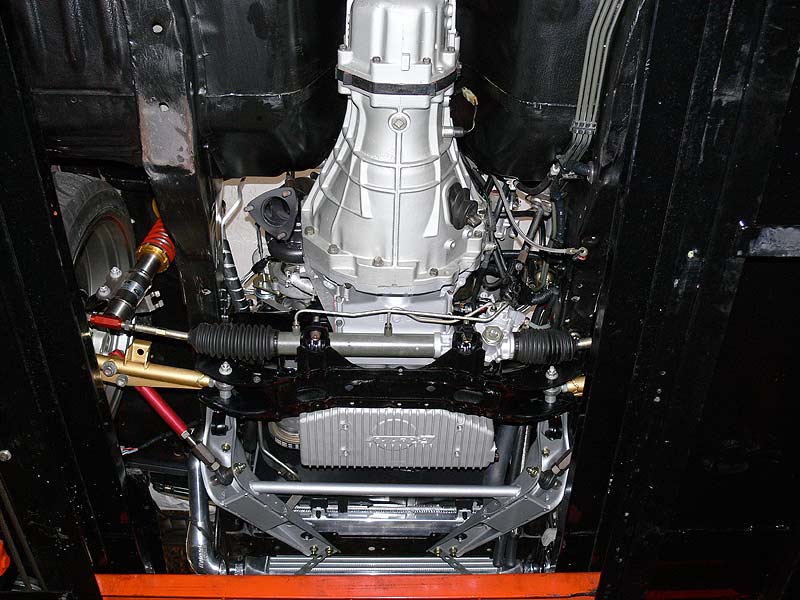

- Under the engine bay

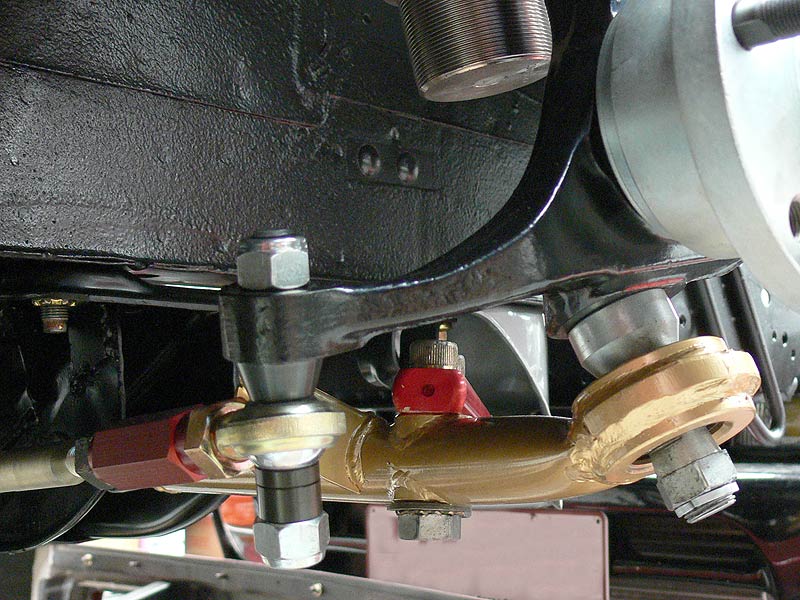

- Front Suspension

- Front Brakes and Coilovers

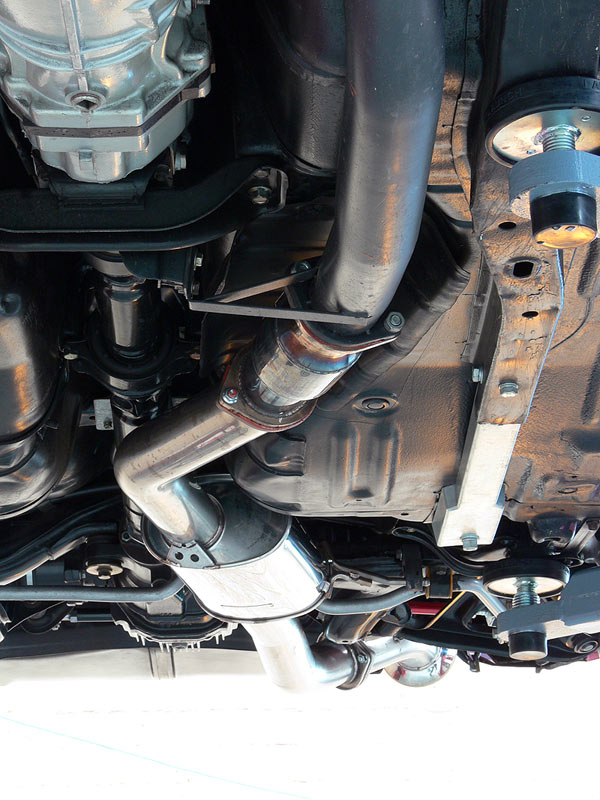

- Front Pipe and Gearbox

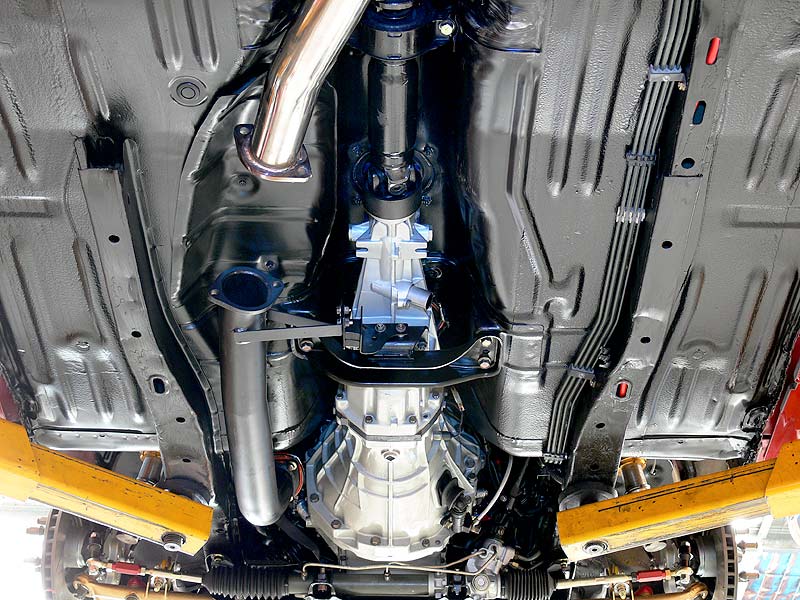

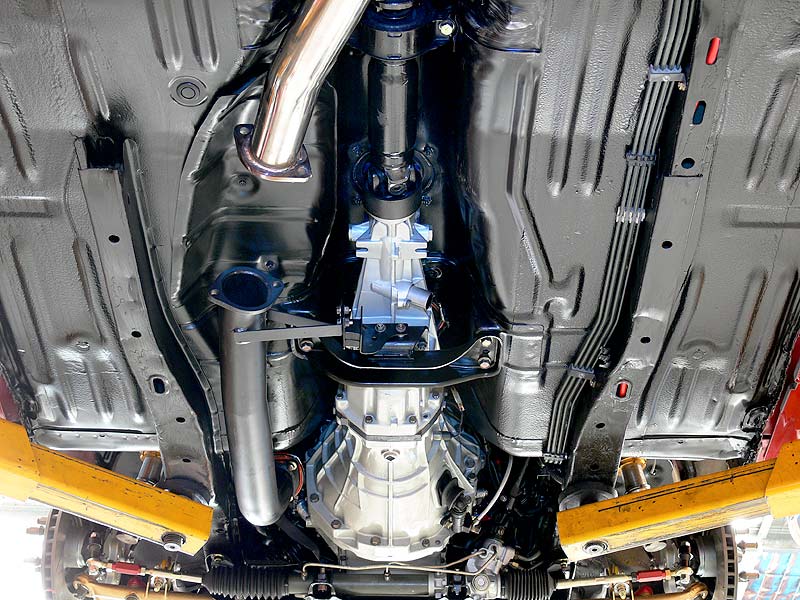

- Rear Subframe assembly

- Rear Suspension

- Air time

The photos that Rick have done so far were really ace, so looking forward to getting a gander at these new ones.

Cheers

Brendan

Thursday, 25 October 2007 | | Categories: Suspension, Wheels/Tyres

Good news first up. After some troubleshooting with the engine, the blokes at C-Red found the problem with the engine. It was found that with the standard shims in place, valves were not able to close completely as the head had basically been over serviced. After ordering a set of undersized test shims in from Precision Shims Australia, the valves were all reshimmed and all is working again. A big thanks goes to Precision Shims Australia...I sent them an email from the workshop on a Saturday morning, I got a call back in 15 minutes from Chris who advised that they were available and could be sent Monday, for delivery by Tuesday. I paid and all said and done...top human.

- Precision Shims storage box

- Shims - from 2.00mm to 3.00mm in 0.05mm increments

In the meantime, as can be seen by the top photo, I have been busy in preparation for compliancing. To ease that process all the adjustable arms have been removed, and a stock set re-fitted. I had this set already cleaned and painted, so it all looks new. Here's the photos of all the adjustable arms laid out on the floor:

- Front adjustable Kazama and Ikeya arms

- Rear adjustable Kazama and Ikeya arms

And here's a couple of pics of the front setup as it is now with the stock arms fitted:

- Front stock arms (from rear)

- Front stock arms (from front)

You can see a small Nismo logo on the front lower control arms, there are original Nismo LCA's, but I've repainted black and applied the logo myself. Also in view is the end of the Whiteline front sway bar.

An interesting result of putting the stock arms back on is the way the rear wheels now fit in the guards. With the Ikeya Formula arms, I couldn't get a good compromise to good fitment, and before the changeover, I had a set of 20mm spacers fitted. Below are a couple of photos with all the stock arms in place (but still lowered on coilovers), and although there's still to have an alignment done, they're sitting pretty.

At this stage, I'm seriously thinking of leaving the stock lower control arms on and not refitting the Ikeya Formula front and rear lower control arms. I think if it was a full race car, that was super super low and full total control over alignment was required, they would be great...but for my purposes, I think they could be overkill. Decision yet to be made. I will however be using all the other Kazama arms including upper camber arms, tension rods and toe rods on the rear, castor arms and tie rod ends on the front.

Now all this time I've been driving the trusty (and rusty) Mitsubishi Sigma (Galant) Turbo around as my daily driver. It's actually a Japanese import, now an Aussie delivered car, and is basically a Starion four door complete with four-wheel vented disc brakes, rear independent suspension and 4G63B engine (Sirius). It's done over 315,000kms and is showing it. The latest item being the driveshaft - with the front universal joint being completely shagged and causing one hell of a vibration. So we had the driveshaft sent off for reconditioning. So what did I drive in the meantime:

I was fortunate enough to borrow Jeff Ash's from C-Red's little Nissan Micra Super S. This little thing although not powerful, was very zippy. Jeff's in his usual mode has changed a few items though, including new front and rear lights, Lenso rims and Tanabe coilovers. This thing, although a little rough, was a great segway from the usual Sigma drive. Think go cart and you're not far off, although I think the beautiful Personal steering wheel and 8-ball gear stick knob had a good deal to do with the driving experience. I also created a little logo based on the March Cup branding use for the K12 March one-make racing series in Japan, and a little Porsche Carrera RS treatment. Some stripes down the lower side including logo may go on in the future.

- Micra from the rear

- Micra from the side

- March Cup logo

Anyway, we're racing to get the car on the road for the next SilviaWA club meet on 7 November. I can't guarantee it, but we're giving it a good go. Because it's a little odd for the club president to be driving around in a Sigma!

Cheers

Brendan

PS> Shameless plug for Woody who's selling Angry13, one of the nicest Nissan S13 Silvia's in Australia.

Wednesday, 3 October 2007 | | Categories: Engine, Interior, Suspension, Wheels/Tyres

Wow, time flies...full stop. But yes, I have still been working on the car. We're currently going through some changes under the bonnet that are taking longer than expected which is causing a knock-on affect in having the car on the road. While this has been happening though, I have been continuing to do things on the car in preparation for its eventual trip over the pits. But first up, I never took photos of the engine bay while at the show which was a complete oversight on my part, so here are a few photos now:

- Engine Bay from front

- Engine Bay from driver's side

- Engine Bay from Passenger side

- Exhaust manifold detail

- GReddy Remote Oil Filter

- GReddy Oil Cooler

You may have noticed in those pics a nice shiny GReddy oil catch can (breather) sitting on the passenger side strut tower. Well this was fitted by me, using a custom mounting bracket and heat shielding that I fabricated (which I was very happy with). Final result looks reasonable clean.

- GReddy Oil Catch Can from front

- GReddy Oil Catch Can from rear

As part of the registration process, there are a number of items that needed to be addressed. The first is the rear high-mount brake light. Now I was originally going to get a Hella light from the local light store (Alanco), but remember that the S13 Silvia came out with one of the factory. As fate would have it, when I had a look on eBay, someone in the east was selling one...and after a frantic last 10sec bidding war, I came away the new owner of a genuine Nissan S13 Silvia High-mount Brake Light.

- S13 Silvia Brake Light (Front)

- S13 Silvia Brake Light (Back)

- S13 Silvia Brake Light (Side)

- S13 Silvia Brake Light (Bottom)

- S13 Silvia Brake Light (Lamp)

Now the sorta trick bit was figuring out how to mount the little bastard (note: it's not that little). After removing the rear parcel shelf (and the sub woofer), I found mounting holes on the metal shelf. Unfortunately the same couldn't be said for the wooden parcel shelf, which I went ahead and guestimated where the holes should be cut after doing a bit of measuring. Next up was figuring out how to get power to it, this is where I could kiss the Nissan engineers as they left the plug sitting on the loom that runs across the rear window. I cut the retaining tape and hey presto, all it plugged straight in. After bolting on the mounting bracket and a few backwards and forwards with the wooden parcel shelf, it was installed.

- S13 Silvia Brake Light Mounting Bracket

- S13 Silvia Brake Light Plug (Wire/Loom)

- S13 Silvia Brake Light Parcel shelf modifications

- S13 Silvia Brake Light Fitted (from inside)

- S13 Silvia Brake Light Working

While on the parcel shelf, I installed the child restraint belt brackets. Now I installed the bolt holes a few months ago, so this was a very simple job. Using the Klippan Child Restraints from Repco (I think), it was just a matter of removing the pre-cut piece in the wooden parcel shelf, a hole made in the material and bolt them in. All done in about 5 minutes, but crucial for registration and taking my 1yr boy for a spin.

- Klippan Child Restraint

- Child Restraint (fitted)

- Child Restraint (fitted)

As the car is getting registered, it will no doubt be subjected to their height test which usually equates to the car needing to be 100mm off the deck at any point under the car. After fitting up the exhaust a few weeks ago, a quick check under the car revealed it had a lot of height required to clear. At only 55mm off the deck, I needed at least another 55mm to get me in the safe zone. The procedure to do so was reasonably easy though with just a matter of taking off the bottom coilover mount and winding both sides out until it all cleared. This was done for the front too, but this consequently cancelled out some of the clearance done on the rear. I'm in two minds yet as to whether I will just put stock shocks/springs on to get the registration process over and done with. Here's a before and after shot anyway:

- Wheel height before

- Wheel height after

- Exhaust clearance after

Another reason for all these delay's is the fact that I'm also spending more time with the family, which means less time on the car...and without doubt, family comes first. I promise not to leave it so long next time (like you've never heard that before from a blogger).

Cheers

Brendan

Monday, 13 August 2007 | | Categories: Engine, Exterior, Suspension

Well it's been a couple of weeks since Autosalon, and during that period it was a time of rest and spending some quality time with the family. Many thanks to all the kind words that I've received...they're coming from all over the place including the US and Europe. But now it's back to situation normal...meaning only about 3hrs a week to work on the car.

So first up last week it was time for the tailshaft (driveshaft) to be installed. Now one thing to keep in mind here, is there hasn't been a tailshaft on this car for close the 3 years, meaning all brackets and bolts are long gone. If you're going to take on any restoration project, got get yourself a very large quantity of plastic snap-lock bags, a permanent marker and a bunch of plastic boxes to store the little bits in. Why? Because when it comes time to bolt things back up, it can take considerable amount of time to find the correct nuts, bolts and/or washers. This time I spent close to 50 minutes finding and then cleaning the tailshaft and centre bracket bolts. Once I had them, it was a fairly simple task.

Then I looked at the rest of the exhaust system. See for the show, I only had the rear section hanging by the rubbers so visually it looked complete. Now it was time for the front pipe, centre section and sometime this week the cat converter. The front pipe is the section between the turbo dump pipe (or Turbo extension as HKS calls it) and the catalytic converter. In my case I have an HKS Dump Pipe and HKS Front Pipe, both of which have been ceramic heat coated. So off I went to get some gaskets and flanges for the cat and dump. Now the 3-bolt gasket I got from Finnex didn't quite fit correctly, so I used the die-grinder to extend the bolt holes. (Note to self, put gasket into vice or you'll ruin the gasket!). After ruining the first gasket (plus wasting more time going and getting another), I had all the bits I thought I needed - and now ran out of time.

So now this weekend just past, it was time to focus on the front pipe. A quick test fit unfortunately revealed that it was going to be hitting the underside of the car. We can only speculate that because we now have nice new Nismo mounts, it was raised the engine up enough to cause the interference. No matter, we used an additional 3-bolt flange as a spacer (plus an additional gasket of course) to drop the front pipe down enough to clear. Yay, it fitted. Then the centre section of the exhaust was put on. Fairly simple affair, but damn that exhaust sealant can get bloody everywhere! With the addition of the mounting point that attaches to the rear subframe bolted up, the exhaust is looking good.

While on the hoist, I removed the wheels in preparation for the brakes to be bled and the cat converter and all the flanges and gaskets are in a single box ready to go on. Not having many pics of the underside, I setup the camera on the tripod and took a few snaps. Here's the results:

- Under the engine from rear

- Under the engine from front/side

- Under the engine from front

- Front Suspension assembly from front

- Front Suspension assembly from rear

- Rear Subframe assembly from rear

- Diff closeup

- Rear suspension assembley

So with these bits done, and the brakes and clutch being filled and bled at some point this week, attention will turn to getting the engine turning over. After that, it'll a matter of getting all the pieces left over sorted so it can be put over the pits. This includes things like the lights, indicators, washer bottle, oil catch can and as well as having an engineer take a look.

I'm so itching to get this on the road...my old Sigma is really showing signs of old age (which after doing 310,000kms is not surprising).

Cheers

Brendan

Monday, 9 July 2007 | | Categories: Interior, Driveline, Suspension

Jeez, the pressure is really on now to get the car done. And now I'm taking a holiday! Last week was a little hectic with a lot of little things to do. Of the main things, the interior is all in (just need to bolt in the glove box once the loom's been tied away), the fuel system is finished, the mirrors are being painted and the carpets are done. The main battery line has been secured in its final resting place, the stereo installer is all set to do his magic (Daniel Jurkovic - 0408 792 466), and Tomas is scheduled to come in later in the week to refit the body kit.

So, how does the trim work look...in two words - bloody fantastical. Pete, Chris and the guys at Trimcare have done a great job, in minimal time and fuss...if you need any trim work done, please don't hesitate to go see them (Trimcare - Unit 3, 233 Bank Street, Welshpool - 9470 3381).

With the floor mats, they used originals as a template for the main shape and had the edges bound. For the specB badge, we mounted in the factory position, but as it wasn't as solid as the original, and the carpet is rather plush, they had to melt the fibres under the badge so it didn't bow in the middle once riveted into place.

- S13 specB Floormats

- S13 specB Floormats (closeup)

- Boot Carpet (centre)

- Boot Carpet (drivers side)

- Boot Carpet (passenger side)

The door trims came up a treat - ignore the whitish tinge, it's chalk marks that I'm yet to clean off. The plastic trims and centre console were all sprayed back to the original black colour, and the gearboot and handbrake cover are now in place. You can also see that the centre console box lid is trimmed in the same material as the back seat, door trims and glovebox.

- Centre Console

- Dash all fitted

- Air-conditioning Controls

I tell you I had a rabbit of a time with the air-con control. Firstly the head unit I had hadn't been cleaned once in its lifetime and it took me 30mins of rubbing hard with the prepsol to get down to the shiny plastic again. Once it was all clean, it was time to fight the octopus which was the wiring. I had to go track down a fuse, and missing solenoid for the airbox - along with a bunch of running around to different cars trying to figure out what went where. I also found one of the Nissan console DIN-sized storage boxes too (woohoo).

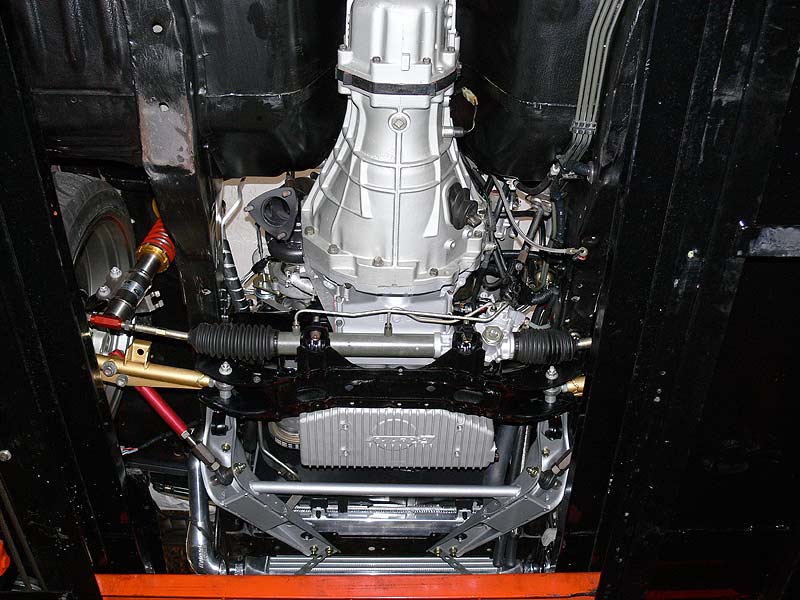

Doing all this work took place on the hoist, so while it was in the elevated position, I took a few pics of the underside for all those that haven't see it yet. Note you may see some flaking red paint in bits which is actually the hoist, not the car.

- Back of gearbox/tunnel

- Diff from the front (R33 GT-R Diff and Half-shafts)

- Diff from the back

- Rear Wheel suspension etc from the back

- Rear Wheel suspension etc from the front

- Front Wheel suspension etc from the back

Taking the weekend off as we've had a place booked down south for quite a number of months now, then next week I'm focussing only on the car to have it ready for Autosalon. Hopefully I can get one more post in before the show.

Cheers

Brendan

Thursday, 28 June 2007 | | Categories: Audio, Interior, Suspension

Didn't the logo come up tops! I'm extremely happy with the way the logo has come out...not to mention the trim so far. The trim is currently in the very capable hands of Chris, Peter and the team over at Trimcare in Welshpool. The rear seats have been trimmed, the vinyl on the door trim has been repaired, and the time the photos were taken, they were still to be resprayed back to factory original colour.

- Door trim insert logo

- Door trim inserts ready for fitting

- S13 Rear Seatback trimmed ready to go

While Trimcare have been working on the cloth trim pieces, I worked on the boot - specifically the rear Cusco Strut Brace and the additional OST brace. Essentially you fit the main brace and centre the bits, then fit the triangulating braces that reach to a plate on the floor. You mark the holes on the floor, drill a nice clean guide hole using a small drill bit, then proceed to drill the main hole. Then get on your back, riggle under the back of the car (mmm, looks so clean under there), and pit the backing plate into position which is just above the differential. I also fitted up the Zenith Boot Brace which ties the ends of the chassis rails together in a similar way to the standard S15 rear boot brace does.

- Holes drilled in boot floor for bottom plate

- Zenith Rear Boot Brace

Of course all these bits will need to come out again, but finding all the bits and making sure it all fits is all part of the process.

Now the plastic trim in the boot usually covers up the top of the suspension towers, so once you fit a rear strut tower brace, it no longer fits. So the solution is to cut holes in the plastic trim so the brace and come through as well as giving enough room to adjust the coilovers damping. With this in mind, and the use of an engraving/dremel tool I set about cutting holes on an already busted set of trims. Using a tape measure and pencil I roughed out a guide to cut. I fitted a 20mm cutting wheel to the dremel and made my first cutouts, cleaning up the corners with a small 8mm diameter grinding stone. Test fitting revealed that the holes could be made smaller, so with that I measured out on the good trims and an hour or so later it was done. These boot trims were also dropped over to Trimcare so that can be refinished in the factory colour. The edges of the holes will get a clean rubber trim put around the edge.

- Suspension tower trim hole (passenger side)

- Suspension tower trim hole (driver's side)

You can see though that the original colour of the car (ie. white) is showing through the holes, so I masked up the area and used some Wurth's Matt Black paint to darken the area. Once the trims go back on, it should look need and tidy.

- Suspension tower painted (passenger side)

- Suspension tower painted (driver's side)

As the paint can was out, I quickly masked up the rear tow loop that sticks out under the rear bar and painted that too. It was looking rather scummy, but I sanded it back and found a cleaner black plastic trim and now it's up to spec. Oh, and considering I was tinkering at the back, I refitted the number plate lights that I had cleaned up. This also involved taking the old tape off the wiring which runs inside the boot and re-wrapping in new tape. With new bulbs in place and a bit of grunting trying to plug them back in (as the plugs are up on top of the steel bumper), all went in without a problem.

- Tow Loop (top)

- Tow Loop (bottom)

- Number plate lights re-fitted

Meanwhile Marc has been completing the wiring loom, the Splitfire coils are in place, the injectors are wired up and there's hardly a wire to be seen thanks to the Marc Palmer Special Service (you really need to look for them). Oh, and all that stereo gear was picked up thanks to Alex at Westside Car Audio in Osborne Park. I got a great deal on the gear, including the DDLinear Flagships. The amps are tiny and much lighter than an older 1000w monoblock is, so it evens out the use of all the dynamat  Now I might have to upgrade my iPod because I need a later version...but that's a tax deduction anyway.

Now I might have to upgrade my iPod because I need a later version...but that's a tax deduction anyway.

Seeya round

Brendan

PS> Apologies for the later than normal posting date.

Tuesday, 16 January 2007 | | Categories: Brakes, Suspension, Wheels/Tyres

The call came about 11.00am last Friday morning from Jeff Ash at C-Red to say my wheels had arrived at the workshop. Although I felt like jumping in the car and racing out there to see them, I held off and waited until Saturday morning.

And was the wait worth it...abso-freakin-lutely! For those who haven't seen previous posts, they're from Japanese manufacturer Weds Co Ltd, and are part of the WedsSport range called the TC105N (released in 2006). These rims are just gorgeous and will suit the build down to a tee. They're very race oriented, with minimal obvious dish, and a spoke the goes from the outer lip into the centre hub which is very important for me aesthetically. The colour, which is best described as Titanium Silver (TS colour code according to Weds). The sizes are as mentioned before:

Front - 18 x 9.5 +10 @ 8.0kg

Rear - 18 x 10.5 +12 @ 8.35kg

They're seriously light and very well made. Here's a selection of pics to help you get a feel for how nice these are:

- WedsSport TC105N

- WedsSport TC105N

- WedsSport TC105N (Detail 1)

- WedsSport TC105N (Detail 2)

- WedsSport TC105N (Detail 3)

Tyres have been ordered in the form of Federal 595SS in 245/40R18 for the front and 265/35R18 for the rears. May even have by weeks end.

The offsets were always going to be hard to guess, especially with such a wide car (as it is now), but we nailed it I reckon. Not that we had much choice we ordered them as big as was available. When it came time to fit them up, I was a little disappointed with the amount they say in the guards, but on closer inspection, it was more that I had not adjusted the camber arms or lower control arms as yet. Here's a couple of shots before and after the adjustment:

- Rear Wheel fitted Before Adjustment

- Rear Wheel fitted After Adjustment

The front is on and sitting out from the guards just a smidge, but again nothing has been adjusted yet and we have about 2-3mm clearance on the coilover at the moment.

- Front Wheel fitted no adjustment

And check this out, it shows how much width I really have front and rear...it just looks so brawny it's nuts! It even has glimpses of GT-R in the rear now.

While in on Saturday, by myself mind you, I managed to get the rear Brembo's fitted up. The pins and retainer clips required a bit of scrubbing with a metal brush to remove some of the baked on brake dust, along with a quick polish. The rear's now fill the rims very nicely. Will get on the fronts this week.

- Rear (R33 GT-R) Brembo Caliper

- Rear (R33 GT-R) Brembo Caliper - Top View

- Rear (R33 GT-R) Brembo Caliper - Fitted

It's been an exciting time getting the rims because it really shows we're getting close now. Just finishing off a couple of private jobs at the moment so I can purchase a few things for the interior (Dynamat, headunit and retrim) so that I have a nice comfy and relatively quiet and cool driving environment.

Until next time.

Cheers

Brendan

Monday, 8 January 2007 | | Categories: Exterior, Suspension

Well well well. Been a while since last post hasn't it. December was a rather busy month getting ready for Xmas. The wife had a deadline of Xmas day to get our front gardens done, so weekends were spent digging, prepping, etc. Glad to say I did make the deadline and we now have a little tropical grotto out the front. So there's the reason for little work being done on Sillbeer.

So after Xmas, I spent a week off to spend time with the family which was thoroughly enjoyable - plus the workshop was closed so I couldn't do anything anyway. Last Tuesday I was in there, and planned to be there for three full days.

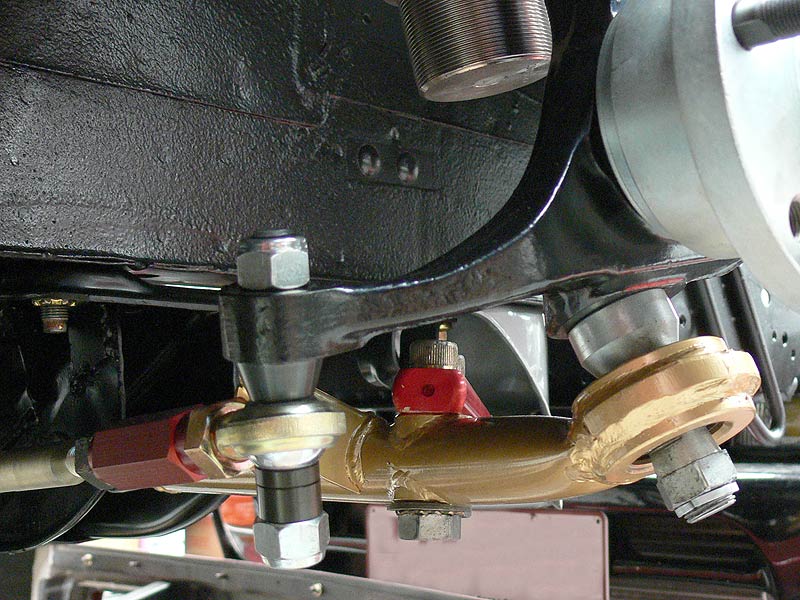

First on the agenda was to get the Ikeya Formula Front Adjustable Lower Control Arms finished off. They are pre-loved items so weren't in top shape, so I sanded them back a little and gave them a fresh coat of gold (not quite Ikeya Formula gold, but close enough for this) along with a coat of clear. The nuts and bolts etc were in pretty used condition, and I didn't have the inclination to sandblast them and electroplate them (funny considering I bought the electroplater for just that reason), so instead I got out the prepsol and a wire brush and gave them a quick once over. They didn't come up too bad either.

- Ikeya Formula Front LCA's prepped for paint

Next on the agenda was getting the windows and window surrounds all ready to have the glass refitted. The rear screen had something on it similar to the dimpled surface of a basketball which took about 2hrs all up to remove it. Ugh!! Then the old sealer was removed and given a good clean. Following on the rear quarter windows were cleaned up and the old tint removed (which was completely clear due to age and sun). The tint glue was especially a pain to get off, using a razor blade certainly helped.

- S13 Silvia Rear Windscreen Glass

- S13 Silvia Rear Quarter Window Glass

Then came the real challenge...chasing down all the bits of surround for the rear, quarter and doors. This probably took a good day and a half to find all the bits, fasteners from about 4 different wrecks that C-Red has for just such a situation. Some bits were even found in puddles of water sitting in the wrecks. In the end, I managed to get all the bits needed, although I will be needing to get new door seals, new front screen along with new front and rear window retainers.

- S13 Silvia Rear Windscreen Lower Surround

- S13 Silvia Door Surrounds and Rubbers

Oh, and I also added a nice boot lock in the form of an old CA version lock, just because I like it better than the SR version.

After the exterior bits, I focussed on find the scuff panels and lower kick panels. These were a little harder to track down, but finally got a full set along with the correct fasteners and gave it all a good clean in the shower, a wipe down with prepsol and finally a good lashing with the tyre shine...now look great (pics don't do them justice).

- S13 Silvia Door Scuff Panel

Following on from the windows and stuff, I decided it was time for a bit of a clean up. Needing access into the boot, all the bits and parts I've been storing in there needed a new home so the side skirts and other body panels waiting to be mounted were stored in a safe place and the parts were moved into the place where the rear seat will go. Giving me access to the boot which was a freakin' mess after spending plenty of time at the panel beaters. I started off with a vacuum, then some all purpose cleaner and finally a wipe down with the prepsol. This should give a nice clean surface for the Dynamat to stick to.

- Clean Boot (left)

- Clean Boot (right)

Now I have been tossing up what sort of engine management I'm going to use for sometime, and wanting to keep it to a good street car with the occasional track squirt, I wanted good cold start functionality and economical freeway/highway driving. So I've decided to give the latest BikiROM a go using an S15 ECU. This will require the need of a Z32 Air Flow Meter, so Jeff ordered in a Bosch one for me - nice and new, and give me good driveability (sp?).

- Bosch Z32 AFM Box

- Bosch Z32 AFM Label/Side

- Bosch Z32 AFM Inside

Something that I've been wanting for get sorted for sometime it of course the suspension, and with all the parts needed now at hand to finish it off, I got stuck into it with only the front and rear lower control arms being the final major bits to go (sway bars will get fitted later - but at least I have them). First up the stock rear LCA's were removed which was relatively easy - remove split pin, nut and them give the hub carrier a few good hits with the hammer and she fell out. Next up I fitted the inner mounts first on the Ikeya Formula Adjustable Lower Control Arms followed by the outer ball joint. Damn it looks good.

- Ikeya Formula Rear LCA's Installed

- Ikeya Formula Rear LCA's Ball Joint 1

- Ikeya Formula Rear LCA's Ball Joint 2

And then it was onto the fitting the fronts which were prepped prior. Once I got the correct installation order for the spacers etc on the ball joints, everything went pretty smoothly. And they look hot too.

- Ikeya Formula Front LCA's Installed 2

- Ikeya Formula Front LCA's Inner Mount

Second last step was to go around and tighten up all the suspension ready to hit the ground followed by the tightening of all the wheel bearing nuts (which I had to go out and buy a 36mm 3/4" socket and 1/2"-3/4" adaptor :( cost = $50). It's now at a stage where the discs and be mounted up, calipers bolted on and wheels fitted. I think I will do this next week so that it can be rolled around the workshop. Josh at C-Red will be completing my engine and gearbox over the next couple of weeks (hopefully) and we can then drop the front suspension, mount the engine and gearbox, and put it all back again with then need to scratch the engine bay.

Phew, that was a big update, 'til next time.

Cheers

Brendan

Monday, 11 December 2006 | | Categories: Suspension

I have managed to get my hands on a set of the Ikeya Formula Rear Lower Control Arms (Adjuster Rear Lower Arms) earlier than expected. These were actually Roy's, but he's kindly let me have them and then he will get mine when they come in from JShop. They're a rather nice bit of kit that's for sure, and I can't wait to get them fitted (and I only just put the damn rear subframe up last week).

- Box

- Label

- Top

- Side

- Documentation

The main function of these front and rear adjustable lower control arms is for roll centre adjustment. Here's a piece of information from the Ikeya Formula web site explaining it further:

Drivers tend to consider that center of gravity would be lowered and have more stability if car height is lowered. However, if you are using the normal arm, the arms would be raised and opened up outwards and the center of gravity of car and roll center would be apart . And the roll amount unnecessarily increases while the suspension stroke decreases, and causes the condition of " Grip limitation between tire and ground surface will be lowered".

By using Ikeya formula's "Front lower arm", "Rear lower arm" and "Tie-rod end" which possess the roll center adjuster function will correct the roll center and set back to the position where has the shorter distance between center of gravity and roll center and then decreases the roll amount.

Additionally, we would like to recommend to install both Front and Rear at the same time. Because the roll center of Front and Rear would be "shifted", if mounting only on Front side, and the roll axis will be shifted on Front and the roll amount changes on Rear, and causes loss of the stability in the car behavior.

From these points, we would like to recommend to wear both on Front and Rear.

Wasn't much work done on Saturday. I had intended to get the engine bay all ready for ancilliaries to be installed by giving it a cut & polish to remove some overspray, but it wasn't budging. I will now give it a rub back and have it resprayed properly. Wouldn't want to do all this work to have a crap looking engine bay.

Cheers

Brendan

Tuesday, 5 December 2006 | | Categories: Engine, Driveline, Suspension, Wheels/Tyres

OK, so here's how it goes. The week before last I went ahead and painted the fuel tank using some of K&H;'s Chassis Black paint. Was touted as being chip resistant yada yada. So after prepping the tank with a quick wet sand using 400 grit paper, I sprayed it on...outside...in the sun. This turned out to be bad move. Number one problem was the dusted, number two was the tank getting hot making the paint finish a little strange and three the slight breeze present was blowing the spray away before it hit the tank. Needless to say I wasn't happy with the finish...plus it was way too shiny.

- Wetsanding the tank

- Finish using K&H; Chassis Black

So I let it dry for a week hoping the shine would subside a little but on Saturday, it still didn't look any good. So out it came for another coat of paint (which in the process of moving it, I scrapped it back to bare metal...so much for chip resistant). I think next time I'd use the VHT Epoxy Paint in Satin Black, but this time I used the VHT Caliper Paint in Satin Black, along with painting it inside for minimal dust flying around. All in all I gave it about 3 coats of this early in the day and the finish was much better and I'm glad I did it. While it was drying, I cleaned up the metal straps that hold the tank in place along with getting a hand from Clint (cceg) to clean the rubber strap covers (so the tank doesn't rub metal-to-metal on the straps). Along with the rubber straps, we cleaned the plastic tank surrounds as well which took a little bit of elbow grease to clean with some prepsol, but was worth it, giving it a final coat of tyre shine to bring it up to spec.

- S13 Fuel Tank Fitted (from front of car)

- S13 Fuel Tank Fitted (from rear of car)

- Fitting rubber nozzle surround

We were on quite a roll on Saturday, and Roy was staying back later than the usual close time so with Clint helping out, we bolted the subframe up and fitted the rear RG V-Stage coilovers as well. As you can see from the photos, it's looking mint with all the Kazama parts in place!

- S13 Rear Underbody 2

- S13 Rear Underbody 3

- S13 Rear Underbody 4

- S13 Rear Underbody 5

Now due to a bit of peer group pressure from Dally and Roy, I've gone ahead and purchased a full set of the Ikeya Formula Lower Control Arms (front and rear, otherwise known as roll-centre adjusters). The reasoning behind this is that I've done pretty much everything else, why not do this as well. The fronts I managed to pick up second hand for a good price (pictured), but the rears will be new and have ordered them through Aston at JShop. I've received the fronts already as they were already in Australia, but the rears will be coming from Japan, so your guess is as good as mine when they'll be arriving...hopefully prior to Christmas.

- Ikeya Formula Front Lower Control Arms for S13 Silvia/180SX

- Ikeya Formula Front LCA Bolts etc

And news just to hand, my rims are on their way downunder...but coming by ship it will be slow going. Should be here later this month or January. And for those who didn't read the previous post back in late May, here they are again:

WedsSport TC 105N

Front: 18x9.5+10 (8.0kg)

Rear: 18x10.5+12 (8.35kg)

I've also ordered in a new steering wheel. The one I had pegged will be fine for track duties, a Sparco #215 Competition Steering Wheel suede job, but I need a durable leather one for daily driving. The winner was a Nardi Rally 35 Deep Corn with about a 90mm dish, black leather and red stitching...perfect!

Cheers

Brendan

Page 1 of 3 pages 1 2 3 >