Category: Exterior

Tuesday, 6 May 2008 | | Categories: Exterior

One of the many things I love about the car, is its 'factory look'. An obvious way I did this was by using the Nissan Aero kit, which is now becoming quite a sort after item. But a couple of other ways was the filling of the front guards original vent holes (a necessity with the A-pillar braces behind) and the way the Tom modified and fitted the fuel filler cap to make it look factory. You see when you normally do widebody guards, you would use the supplied fuel filler cap which bolts up in the original located and looks like an after thought because it has chamfer on one side to clear the body. Here's an example:

I don't want to say that this car is by any means less worthy, it's a very nice ride. But in my case, the extra effort that Tom made in building up the flap with a small amount body filler and shaping it to suit the new rump really has made a huge, if mostly unnoticed difference...what you want really.

Here's some close up pics on how it looks/works:

- With the fuel flap open

- Closeup of the hinge, silicon hose used for spacers/bolt covers

- Screws used to set the stop point

- Closeup of the stopper screws

- Just a fancy shot of the Spec-B badge while I was at it

The spring on the inside of the flap needed a bit of adjustment so that when the fuel filler flap catch inside was pushed, it popped open. The final product though is just perfect. Thanks Tom.

Cheers

Brendan

Tuesday, 6 May 2008 | | Categories: Brakes, Engine, Exterior, Driveline, Suspension

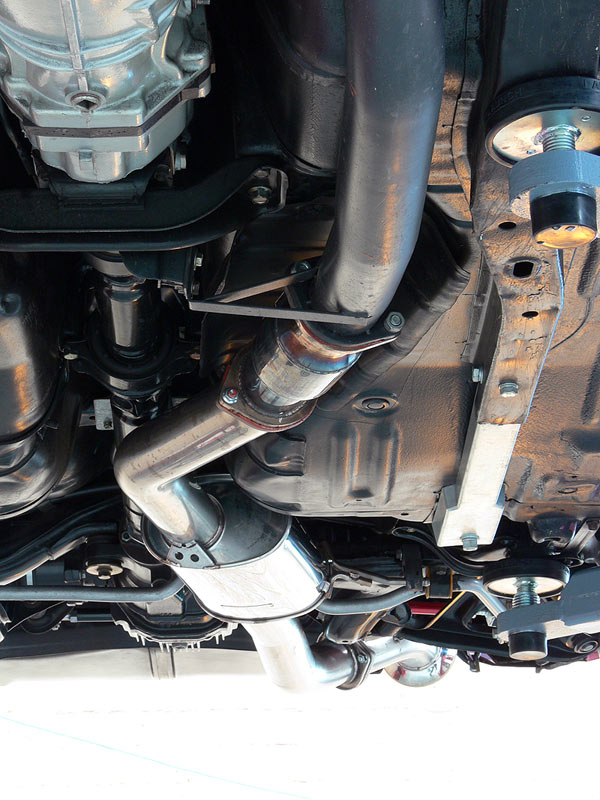

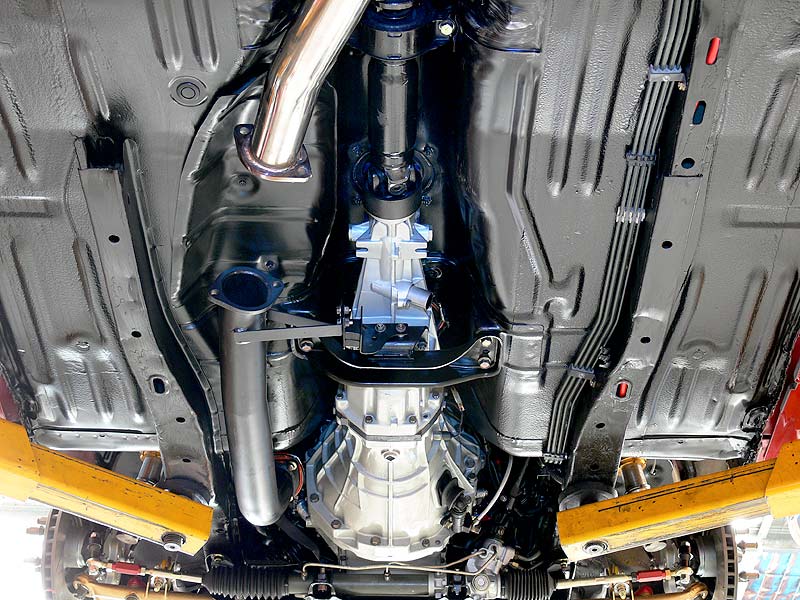

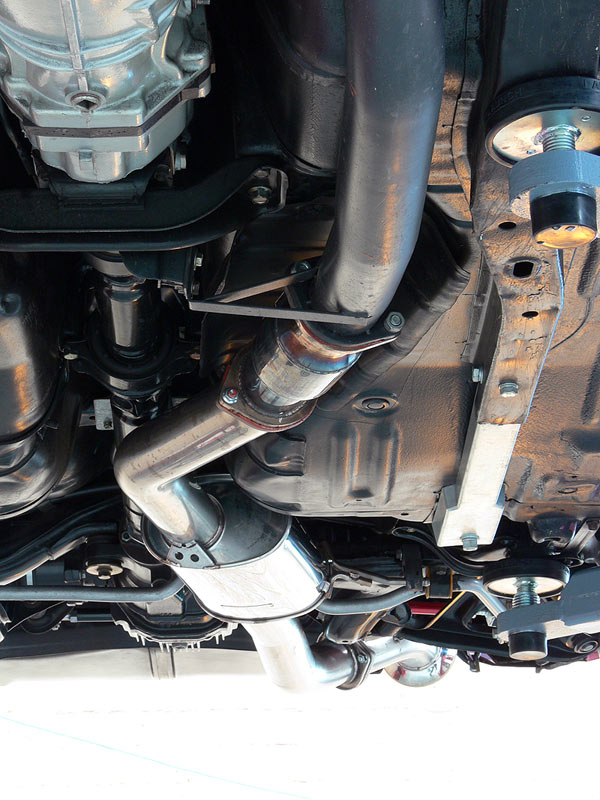

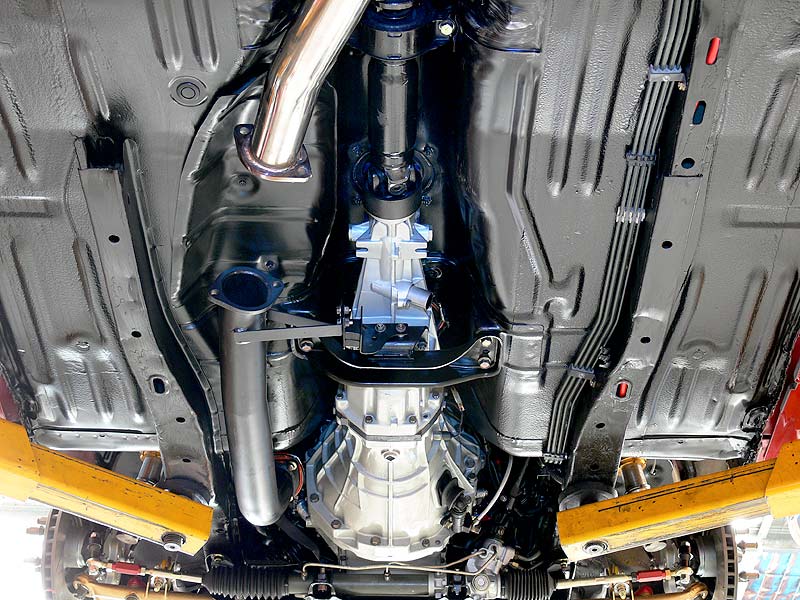

A number of weeks ago now, I did a photoshoot with Rick McDowell, a well known WA based photo journalist. The results of which were brilliant, but with a fair amount of work gone into the undercarriage, and an award to prove it, we needed to get some photos done of the underbelly along with additional engine and interior shots. This being something best done on a hoist of course, so last Saturday we were lucky enough to get some time on the hoist in the C-Red workshop (thanks to Marc, C-Red's Workshop Manager). I went in and first detailed the engine bay, which wasn't too bad really. But as I drive this on a daily basis, and that the road near work as had some work done on it recently (plus rain), I had quite a lot of dirt and mud built up under the guards. With the help of the trusty truck wash and a bit of elbow grease (and mess on the floor) the front and rear suspension on the passenger side came up a treat.

While Rick was snapping away, I thought I'd take the chance to update the undercarriage shots...being there's no longer the Ikeya Formula lower control arms in place, and the exhaust has been completed and changed since the last set I did 6mths ago or so. A couple of things to note though, first being the URAS Floor Reinforcement Kit which extends the chassis rail on the passenger side from the usual S13 cutoff point to the rear. Also, if you look on the drivers side, there's dirt there just to prove that it does indeed get driven. On a whole, I was surprised at how clean the undercarriage is considering the rain we've had lately. Having the fresh'ish paint surfaces certainly helped in cleaning it all up easily though.

Anyway, photos for all to enjoy:

- Rick taking his photos

- Under the engine bay

- Front Suspension

- Front Brakes and Coilovers

- Front Pipe and Gearbox

- Rear Subframe assembly

- Rear Suspension

- Air time

The photos that Rick have done so far were really ace, so looking forward to getting a gander at these new ones.

Cheers

Brendan

Thursday, 15 November 2007 | | Categories: Exterior, General

I've read that a few people had downloaded the images from the latest photoshoot and used as their desktop, so I thought I'd pump a few dedicated images out at varying sizes for those that wish to use them. Enjoy.

Desktop 1

- 1024 x 768

- 1280 x 960

- 1600 x 1200

- 1920 x 1200

Desktop 2

- 1024 x 768

- 1280 x 960

- 1600 x 1200

- 1920 x 1200

Desktop 3

- 1024 x 768

- 1280 x 960

- 1600 x 1200

- 1920 x 1200

Desktop 4

- 1024 x 768

- 1280 x 960

- 1600 x 1200

- 1920 x 1200

For help on using these as Desktops or Wallpapers, just do a search for it on Google.

If there's any specific ones you want from previous photos, leave a comment and I'll see what I can do.

Cheers

Brendan

Wednesday, 14 November 2007 | | Categories: Exterior, General

Photo Gallery

Alright, a couple of people were having a whinge at me for not having photos up, so I quickly popped out and took some so here they are.

Enjoy

Brendan

Monday, 13 August 2007 | | Categories: Engine, Exterior, Suspension

Well it's been a couple of weeks since Autosalon, and during that period it was a time of rest and spending some quality time with the family. Many thanks to all the kind words that I've received...they're coming from all over the place including the US and Europe. But now it's back to situation normal...meaning only about 3hrs a week to work on the car.

So first up last week it was time for the tailshaft (driveshaft) to be installed. Now one thing to keep in mind here, is there hasn't been a tailshaft on this car for close the 3 years, meaning all brackets and bolts are long gone. If you're going to take on any restoration project, got get yourself a very large quantity of plastic snap-lock bags, a permanent marker and a bunch of plastic boxes to store the little bits in. Why? Because when it comes time to bolt things back up, it can take considerable amount of time to find the correct nuts, bolts and/or washers. This time I spent close to 50 minutes finding and then cleaning the tailshaft and centre bracket bolts. Once I had them, it was a fairly simple task.

Then I looked at the rest of the exhaust system. See for the show, I only had the rear section hanging by the rubbers so visually it looked complete. Now it was time for the front pipe, centre section and sometime this week the cat converter. The front pipe is the section between the turbo dump pipe (or Turbo extension as HKS calls it) and the catalytic converter. In my case I have an HKS Dump Pipe and HKS Front Pipe, both of which have been ceramic heat coated. So off I went to get some gaskets and flanges for the cat and dump. Now the 3-bolt gasket I got from Finnex didn't quite fit correctly, so I used the die-grinder to extend the bolt holes. (Note to self, put gasket into vice or you'll ruin the gasket!). After ruining the first gasket (plus wasting more time going and getting another), I had all the bits I thought I needed - and now ran out of time.

So now this weekend just past, it was time to focus on the front pipe. A quick test fit unfortunately revealed that it was going to be hitting the underside of the car. We can only speculate that because we now have nice new Nismo mounts, it was raised the engine up enough to cause the interference. No matter, we used an additional 3-bolt flange as a spacer (plus an additional gasket of course) to drop the front pipe down enough to clear. Yay, it fitted. Then the centre section of the exhaust was put on. Fairly simple affair, but damn that exhaust sealant can get bloody everywhere! With the addition of the mounting point that attaches to the rear subframe bolted up, the exhaust is looking good.

While on the hoist, I removed the wheels in preparation for the brakes to be bled and the cat converter and all the flanges and gaskets are in a single box ready to go on. Not having many pics of the underside, I setup the camera on the tripod and took a few snaps. Here's the results:

- Under the engine from rear

- Under the engine from front/side

- Under the engine from front

- Front Suspension assembly from front

- Front Suspension assembly from rear

- Rear Subframe assembly from rear

- Diff closeup

- Rear suspension assembley

So with these bits done, and the brakes and clutch being filled and bled at some point this week, attention will turn to getting the engine turning over. After that, it'll a matter of getting all the pieces left over sorted so it can be put over the pits. This includes things like the lights, indicators, washer bottle, oil catch can and as well as having an engineer take a look.

I'm so itching to get this on the road...my old Sigma is really showing signs of old age (which after doing 310,000kms is not surprising).

Cheers

Brendan

Thursday, 26 July 2007 | | Categories: Exterior, General, Shows

Photo Gallery

Here's a few photos I took while waiting for the truck to come and take sillbeer off to Autosalon last Friday night. They're a bit rough, but it shows the potential for some nice pics in the future.

If anyone is wanting a larger, desktop/wallpaper sized photo for their machine, let me know and I'll post a small selection up in a few different sizes.

Enjoy

Brendan

Wednesday, 4 July 2007 | | Categories: Exterior, Interior

Last Friday was a big day for me. It was the day the windows were being installed...finally changing sillbeer from a shell, to a car. But before they were done, I had to do some final prep. The interior needed to be removed for one, and the last bit of Dynamat was applied to the rear parcel shelf. While the rear glass was still out, I also drilled some holes for a future harness bar that we'll mount across the parcel shelf because once the glass is fitted, the area will be too tight for a drill.

- Dynamat on rear parcel shelf

Now once the windows were fitted by the kind fellows from Wayne's Windscreens, I took some pictures to remember the moment...you can tell now it's completely changed the outlook of the car.

- Windows installed from rear

- Windows installed from above

- Windows installed from above rear

While that was all going on the last of the interior pieces were gathered together and taken down to Trimcare to be refinished. You can see from the pics that some of the pieces were painted in a marble effect paint...this just isn't my bag, so it'll be brought back to stock.

- Centre console with marble effect paint

- Interior pieces for refinishing

Now as much as I wanted to on Saturday, I had to wait the obligatory 24hrs for the window sealant to cure so I've split my weekday in the workshop this week and spent the Monday PM refitting the interior (well what I had of it anyway). This included the newly trimmed rear seats and front door panels.

- Rear Seats now in place

I even sat in the back and belted myself in to see how comfy it is. I must say the logo really works well. I also went down to Clark Rubber and picked up some nice trim for the holes over the rear strut towers where the brace comes through. The final product looks great, noting also the plastic trim now looks new.

- Rear Strut Tower trimmed and ready to go

Now one thing that I've been trying to solve is the problem with the Nardi boss kit just not covering up the hole in the steering column surround. I did a bit of research and the only ones that seemed to be what I needed were from Nismo. After chasing that up and finding out they're discontinued, I turned to the Yahoo Auctions...and found quite a few of the correct design. Now whether they're genuine Nismo or not is yet to be determined, but I bid on two of them and won both so hopefully they'll be sent over asap. Oh, and I used Slidewise Imports to do all the dirty work, thanks Zac. Here's some pics of the boss kits I won:

- Nismo 'Style' Boss Kit for S13 - 1B

- Nismo 'Style' Boss Kit for S13 - 1C

- Nismo 'Style' Boss Kit for S13 - 2

And finally on Monday I got my Ganador mirrors. Bought from someone on NS.com, they're in great condition and have been dropped off to Phil at AFM Enterprises Osborne Park to be resprayed in the correct colour:

- Ganador Mirros from Front

- Ganador Mirrors from Top

- Ganador Mirrors sail

- Ganador Mirrors plug

Only three weeks or so now until Autosalon so the race is really on to get the car completed. Yet to do are bodykit fit, fuel system completion, catch can, stereo and battery along with a myriad of small bits and pieces.

Wish me luck, going to need all of it.

Cheers

Brendan

Thursday, 5 April 2007 | | Categories: Engine, Exterior

Well it had to happen, especially after the high of the last post...seeing Sillbeer in the sun...a boring bit has descended. Not that it's any less significant, I mean without a wiper motor I'd be totally fubar in the rain. But the headlights do look mean.

So for this post I'm reporting on 3 main things, the first being the finding, cleaning and fitting of a wiper motor. I'm glad there was only one, because it was a pain to clean. For those looking to undertake such a project, parts that have the oiliest coating, are usually easiest to clean and bring up like new. This is because the metal hasn't had a chance to corrode. Unfortunately the wiper motor had corrosion on the aluminium casing and the painted cover so it took about an hour or so to clean up. I did contemplate just buying a new one, but that would cost easily between $200-$300.

- Wiper Motor 1

- Wiper Motor 2

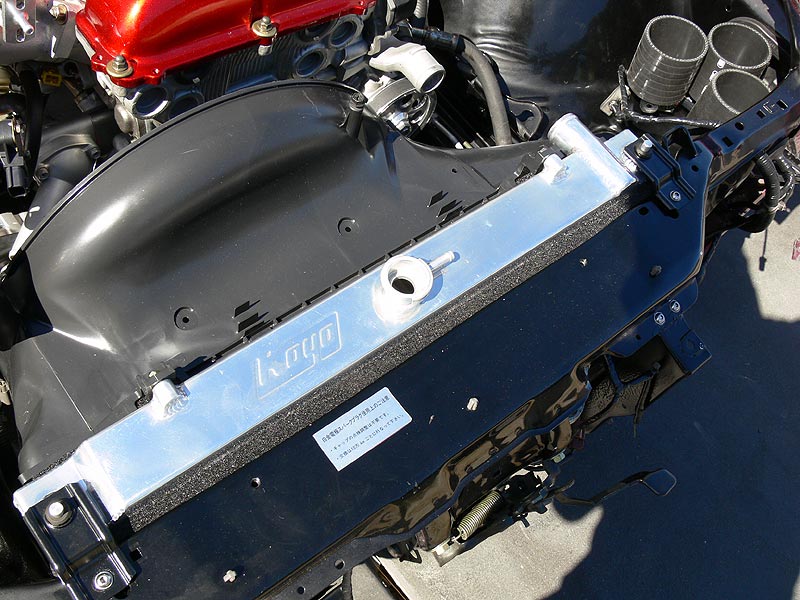

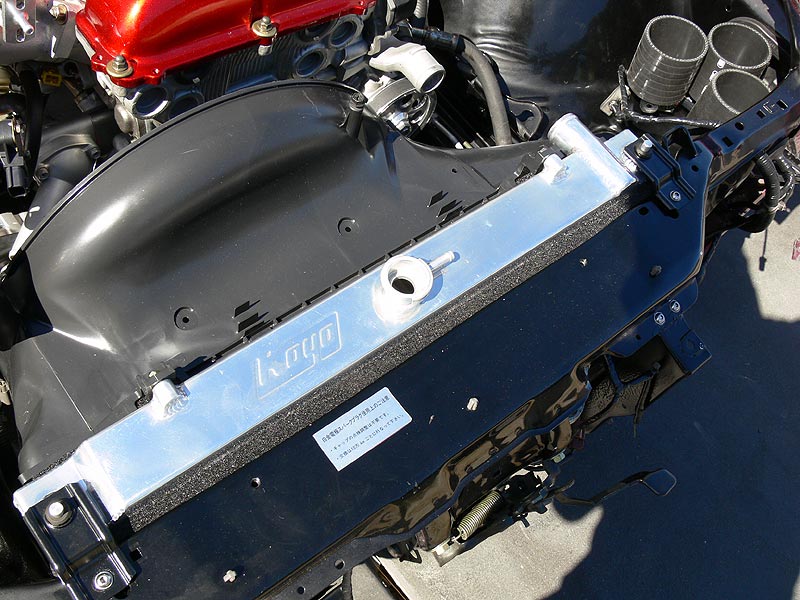

The next thing to report on is the intercooler. It's now mounted (as seen in the top pic) and the attention to detail on the top mount is amazing. The boys went to the effort of cutting the bracket around the shape of the logo (following the shape of the 'b'). I mean you'll never see if once the bumper is on, but you'll see it now:

- Hybrid Intercooler top mount

And lastly is a few odds and sods. The headlights have been cleaned up with some degreaser and doused with silicon spray (ie. tyre shine) to give some moisture back into the plastics. The power steering reservoir was also given a clean, sand and paint along with all the hoses also getting a good coating of silicon spray. The original intention was to mount the white plastic reservoir from an S15 Silvia/200SX, but it was going to be too much of a pain to fabricate and modify mounts when this was going to do just as well. Not that you can see in this set of photos, I've also found, cleaned and silicon'd a carbon canister and hoses which is now mounted in place next to the radiator. And finally, with the necessity of monitoring engine vitals a must, the water temp sensor has been mounted. I had bought a water temp sensor adaptor which usually would get mounted on a cut and shut top radiator hose, but instead some bright spark at C-Red suggested mounting on the top of the pipe leading into the thermostat where there's a small flat spot. So it was drilled and tapped a hole and mounted up the sensor - looks and fits mint.

- S13 Square Headlights cleaned

- S13 Power Steering Reservoir

- Defi Water Temp Sensor mounted

Oh, and a start was made on the rest of the intercooler piping which has been continuing on this week with the mounting of a K&N; Filter (test fit for time being) and the Z32 (300ZX) Airflow Meter. The main deal with this is that we have to mount the huge GReddy Type-R Blow-off Valve somewhere. Having just been down the workshop at lunch, I must say the solution they've come up with looks fantastic and will work a treat. I was sworn not to post pics until it's all welded, blasted and painted, so you'll just have to wait until later next week.

- Z32 Airflow meter/Intake Pipe

So that's it for this week, wish everyone a happy easter period and please drive safely.

Cheers

Brendan

Monday, 26 March 2007 | | Categories: Engine, Exterior, Wheels/Tyres

Progress is happening, but to coin the old phrase, the devil is in the detail is an understatement. And with two of the most anal people I know (Greg and I) working on the project, everything must be done to the best of our abilities (his are higher in this regard than mine). This last week or so has been spent getting the A/C condenser cleaned (and fins straightened), more rummaging through wrecks getting much needed pipe work and bits and pieces. The radiator, an S14 Racing Gear jobby (re-branded Koyo), is now in place along with the S14 shroud. There was a plan to fit up thermo fans, but we've changed tack now and gone back to the clutch fan and shroud. I went and got some foam and rubber stripping for Greg to use in the radiator mounting and the job is beautiful. You'll see the foam in and around all the gaps in the pics above and below.

- Air conditioning Condenser Installed

- Grex (Trust/GReddy) Oil Filter Sandwich plate for Oil Cooler and Remote Filter mount

On Saturday, I decided it was time for Sillbeer to get some Vitamin D, so with the help of Josh and Woody, we pushed it out into the sun and OMG...isn't it just jaw droppingly beautiful. It's the first time I've seen it from the rear as it's usually parked up in front of a wall. You really see how wide those guards are and the width of the tyres isn't really as big as first thought. Our current thinking is that some spacers will be required to get the rims out to the lip, but that will come after she's up and running. The view from the front is just awesome, looking more like it's about to pounce with those massive guards looking more like a danish strong man's shoulders...grrrrr (sorry lame). The colour really is shown a lot better in the sun, with a slight orange shown in the highlights that compliment the wheels. And speaking of wheels, they just shine. So enough of my rabbling, enjoy the pics:

Sillbeer in the Sun:

- Front View 1

- Front View 2

- Front View 3

- Rear View 1

- Rear View 2

- Rear View 3

- Side View 1

- Side View 2

- Front Wheel

- Rear Wheel 1

- Rear Wheel 2

- Engine Bay

- Colour close up

Breathtaking hey?

Anyway, this week it's onto fitting up the Hybrid Intercooler and GReddy Type-R BOV. Because of the size of the BOV, this is where our main problems will lie. It will be plumbed back, as I don't really want huge noise, it will be loud enough just coming back through the air filter. The intercooler couplings etc have now all be replaced from the standard blue silicon to some Samco Black silicon pieces. A big thanks goes to Steve at Hyperflow (the Australia distributors for Samco hoses) in Sydney for sending these over so quickly. Much appreciated.

Speak to you all later.

Brendan

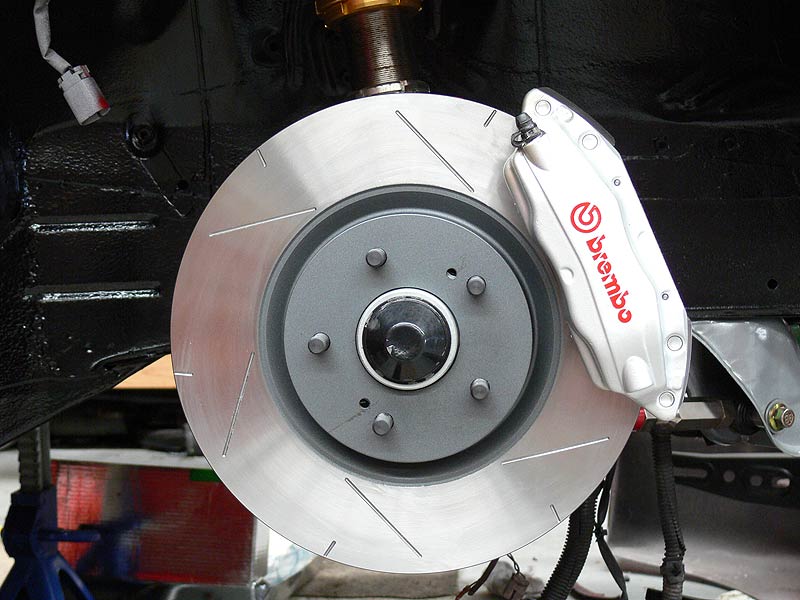

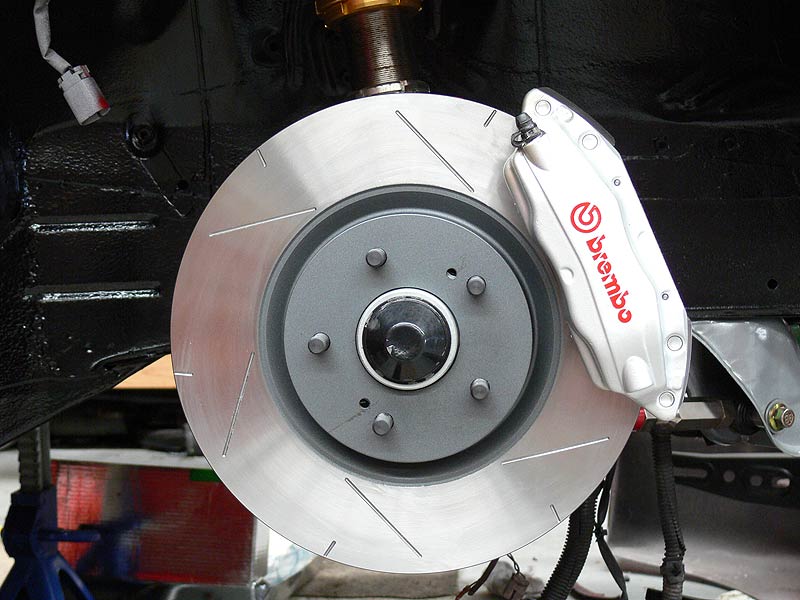

Tuesday, 23 January 2007 | | Categories: Brakes, Exterior, Wheels/Tyres

So Saturday morning I was very excited know that today was the day I'd get to see my car finally with some proper shoes on. Firstly though, I made a quick dash down to Jap Parts Plus to pick up a drivers side window glass, regulator and motor as my door was just empty (thanks to Raj at JPP). Then swung back through to Exley's Tyre Service in High Road, Willeton to grab the wheels which had been fitted with the tyres (thanks Shane). Quite a few people commented on how fine they look while I was there...and after squeezing them into the Sigma, it was off to the workshop for some rubber love.

Before I could fit up the wheels though, I needed to complete the fitting of the calipers. One was already assembled, so after pushing the pads out a bit to clear the the massive DBA rotors, the front 4-spot Brembo calipers were bolted on. They look bloody fantastic.

So with a quick adjustment to the rear camber to bring reduce a lot of the negative camber that was in it, the rims went on. One that really strikes you is the solidness that you get when fitting large rims and tyres to a car of this stature. I mean when you stretch tyres on big rims too much, IMHO it looks too 'try hard'. These look like they were meant to be there...a little GT-R'ish from the rear too. You'll notice I have quickly chucked in the rear taillight to see how it looks. I was a little unsure before fitting it up that it would look cheap, nasty and common seen as quite a few people have them now, but I love it...looks factory.

- WedsSport TC105N Fitted - Rear Quarter view

- WedsSport TC105N Fitted - Side view

- WedsSport TC105N Fitted - Rear Wheel closeup

- Sillbeer wrapped up tight...night night

So, now that that little climax is over, it theoretically can roll...although I should connect up the steering rack so it can be coaxed into a particular direction now. Really need to get stuck into the engine bay, engine and gearbox now...and for those that haven't read previous posts, the engine is built, the gearbox needs doing.

Cheers

Brendan